WIKI 90JS

Vickers, Knoop and Brinell hardness testers with load cell for versatile application

Vickers, Knoop and Brinell hardness testers with load cell for versatile application

|

WIKI 90 JS

|

|||

|---|---|---|---|

| Standard |

DIN-EN-ISO 6506 / DIN-EN-ISO 6507 / DIN-EN-ISO 4545 / ASTM E-92 / ASTM E-384 / JIS B 7734

|

||

|

X/Y Stage

|

manuel – 100×100 mm – 10 μm Schritte | ||

|

Z-Drive

|

0/135 mm manual

|

||

| Depth capacity |

163 mm

|

||

| Evaluation | manual focus with auto reading | ||

| Testforces | 0.09807 – 0.1471- 0.1961 – 0.2452 – 0.4903 – 0.9807 – 1.961 – 2.942 – 4.903 – 9.807 – 19.61 – 29.42 – 49.03 – 98.07 N (0.01 – 0.015 – 0.02 – 0.025 – 0.05 – 0.1 – 0.2 – 0.3 – 0.5 – 1 – 2 – 3 – 5 – 10 kg)optional: From 0.0098 – 0.09807 N (1 g – 10 g) From 98.1 – 612.9 N (10 – 62,5 kg) |

||

|

Feasible scales

|

Vickers

Brinell and Knoop on request

|

||

| Accuracy |

Better than 0.05 %

|

||

6-Position Revolver with upto 4 mangnifications and 2 indenters for Vickers, Brinell and Knoop

With software based focus, image optimization, shading correction and adjustable light source it is possible to create multiple patters with several indents and a high repeatabiltiy with a high tolerace on the surface preparation.

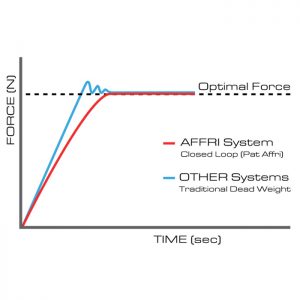

The force will be applied with a loadcell in “Cloesd Loop” matter with a regulation frequency of 1 khz. The results won’t be affected by structural deflection, miss alignment or vibrations.

That increases the accuracy in comparison with conventional “Death Weight” loading systems.

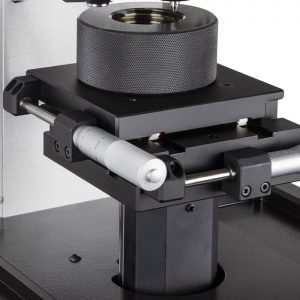

Manaul 100 x 100 mm XY-Stage for several types of patterns like CHD or welding.

As option with digital micrometers!

Ergonomic handwheel for Z-axes control.

The vertical spindle prohibits perfect stability for several samples and mounts.