WIKI JS

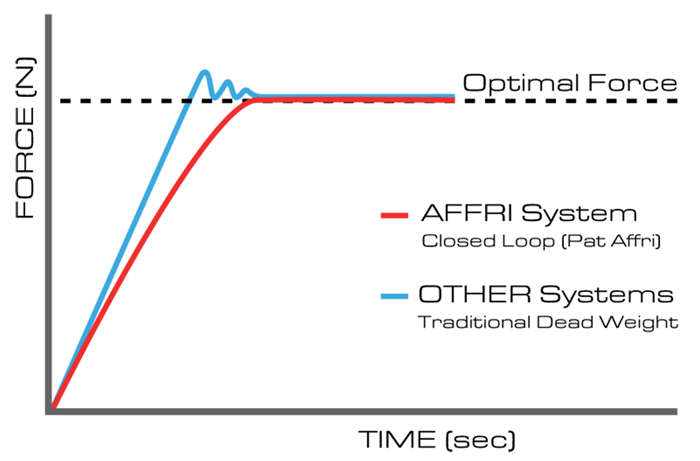

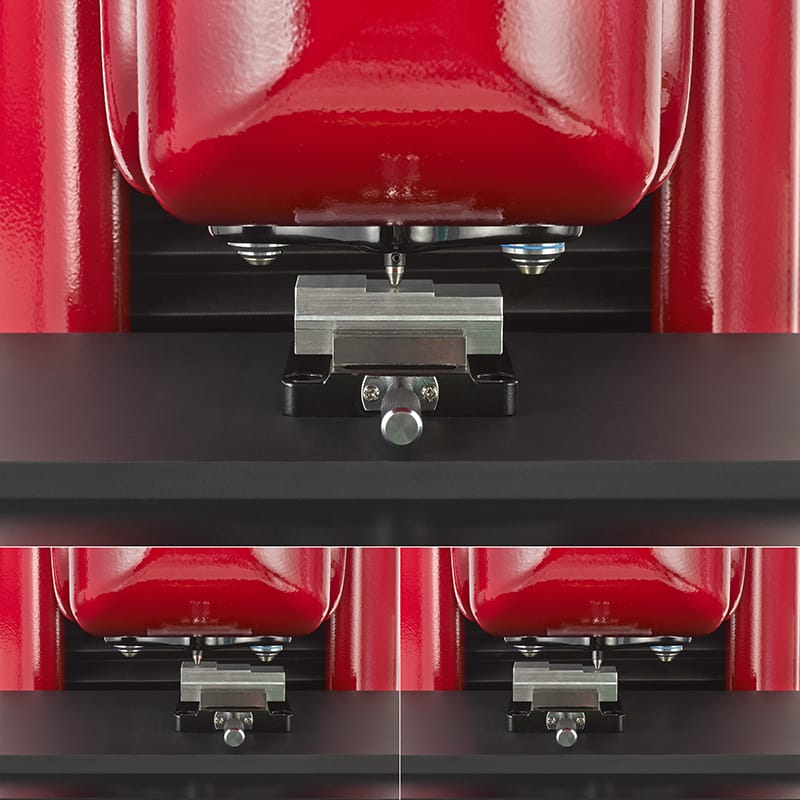

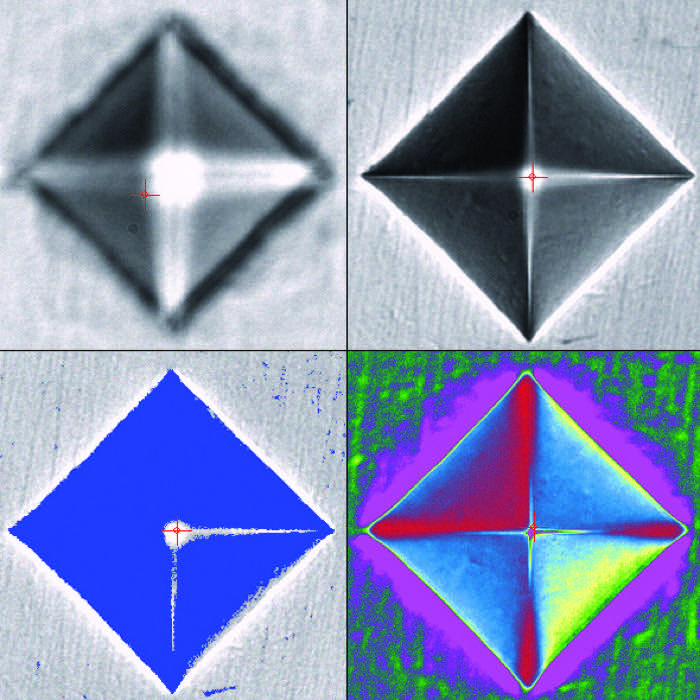

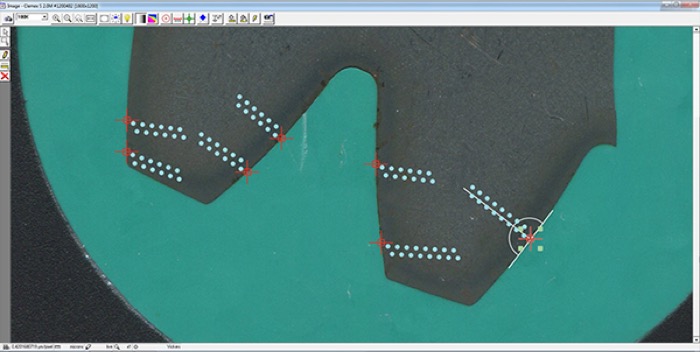

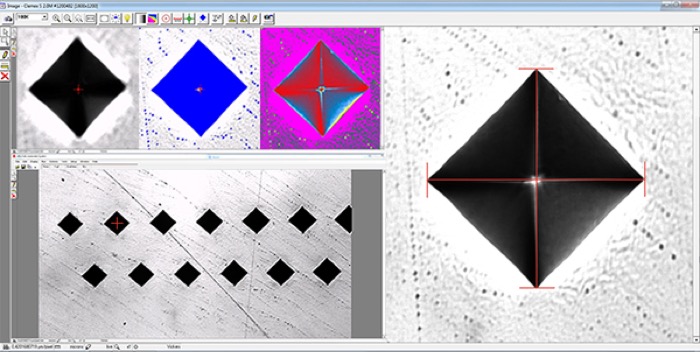

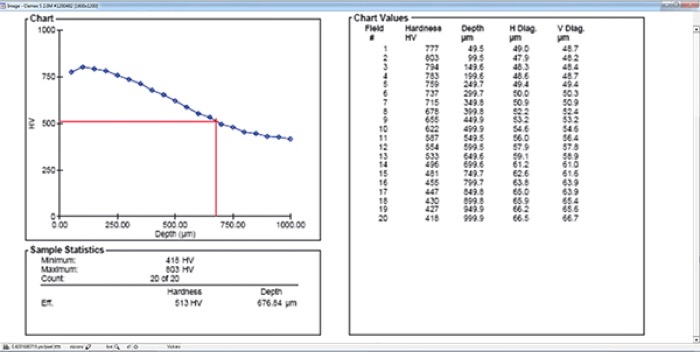

Automatic Hardness tester for micro and macro Vickers, Knoop, Brinell and Rockwell test methods. WIKI JS is the top-of-the-line of automation and accuracy for Vickers and Knoop hardness measurements in compliance with ASTM and ISO hardness standards. It is a fully motorized system for Case Hardness Depth test (CHD) on single or multiple samples in automatic cycle. Everything is automated, freeing users for other tasks and minimizing subjectivity associated with human intervention. Just map-out indentation traverses where they are required, set the load and press START, the hardness tester intelligently follows the predefined patterns, indents the sample, focuses when needed, measures, and generates data dynamically. Load forces are applied through load cells and electronically controlled in “Closed Loop” (Pat. AFFRI) with a frequency of 1 khz, assuring perfect linearity in every range, even on very low loads. For micro-macro Vickers and CHD case depth tests on all metals: iron, steel, tempered steel, cast iron, brass, aluminium, copper and metal alloys. Heat treatment, hardening, nitriding, cementation and hardfacing. Knoop test on ceramic and glass materials.