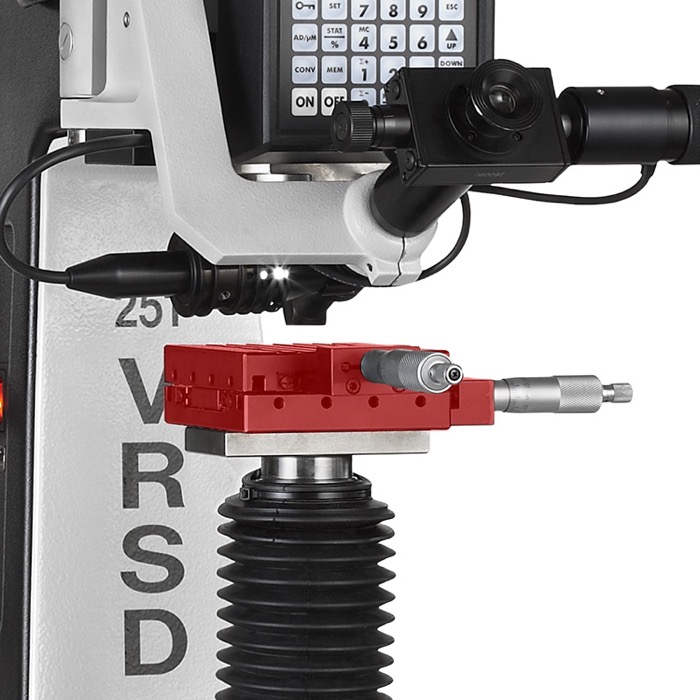

SERIE VRS

Universal hardness tester for micro/macro Vickers, Knoop, Rockwell, Superficial Rockwell, Brinell and Shore test methods, in compliance with ASTM and ISO hardness standards. VRS Series are top level bench hardness testers for tough or lab applications. Fully motorized for fully automatic test cycles, with Vickers and Knoop indentation autoreading through a CCD high resolution camera and the relative software. Absolute accuracy (better than 0.5 %) in every condition. Load forces are applied through load cells and electronically controlled in Closed Loop (Pat. Affri). Exact hardness result on the first test and R&R data are at the top of its class. Digital durometers with LCD screen, user friendly interface, real time statistics and graphs and large archive storage. Hardness tests on all metals: Iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys. Heat treatment, hardening, nitriding, cementation and hardfacing. Hard and soft plastics. Knoop test on ceramic and glass materials.