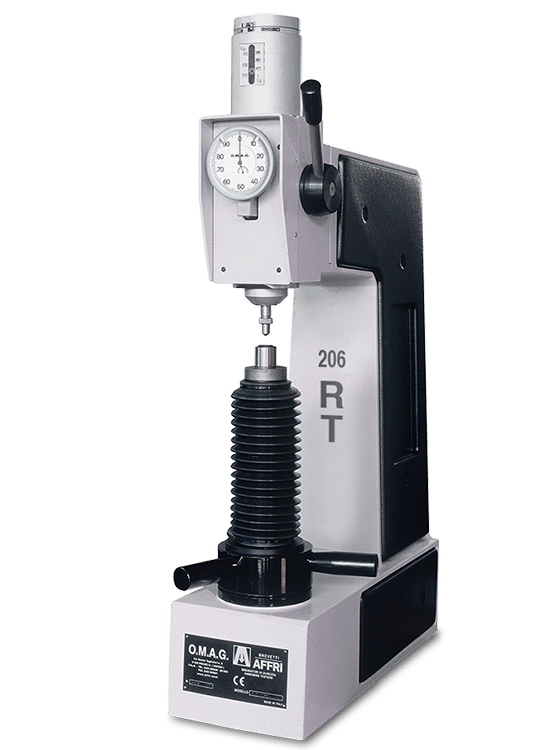

SERIE DRM/EX/RT

250 DRM – 206 EX – 206 RT

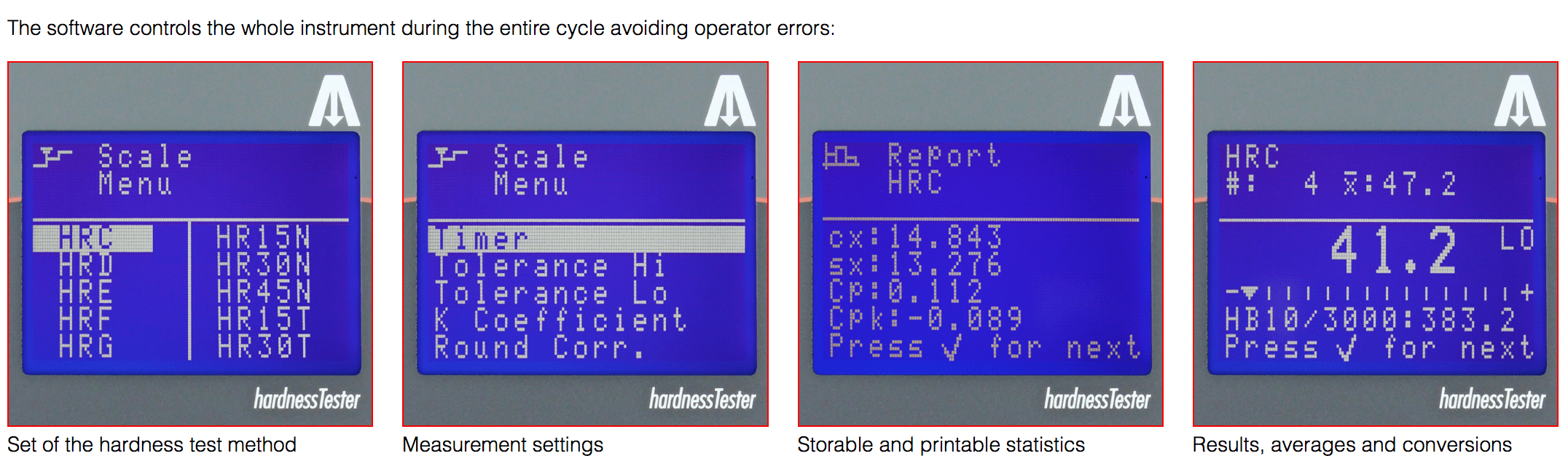

Semi-automatic hardness testers for Rockwell, Superficial Rockwell, Brinell and Vickers hardness test methods in compliance with ASTM and ISO standards. DRM, EX and RT are low cost bench hardness testers with high accuracy standards. To perform the test just act on the elevating screw and bring the sample to make contact with the indenter, pull lever/ push button and within seconds results appear. Load forces are applied through a load cell system which eliminates problems associated with dead weight systems on traditional testers: not affected by vibration and no need to be leveled; work in any condition, even inclined, due to the Affri System where load forces are directly applied along the indenter’s axis, without ratios and levers. Hardness testing on all metals: iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys. Heat treatment, hardening, nitriding, cementation and hardfacing.