RSD MAG

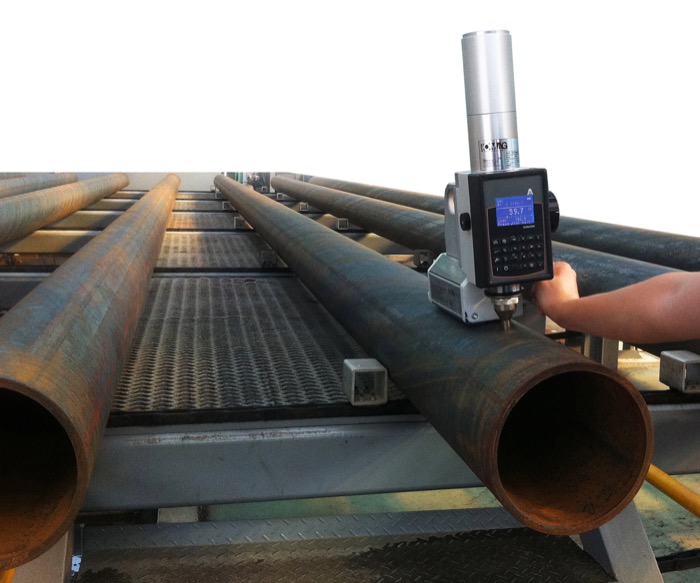

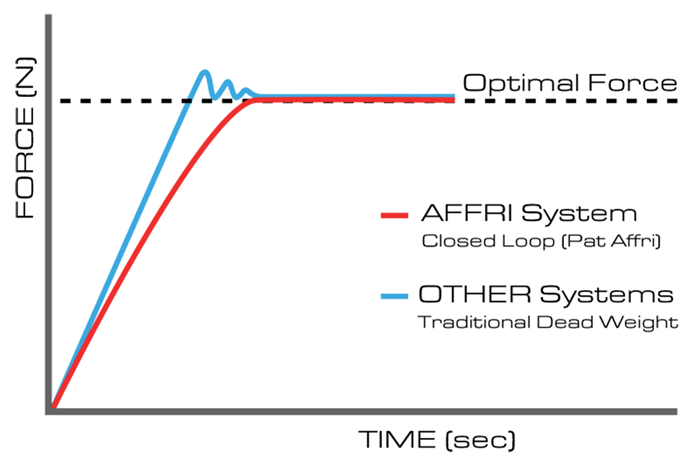

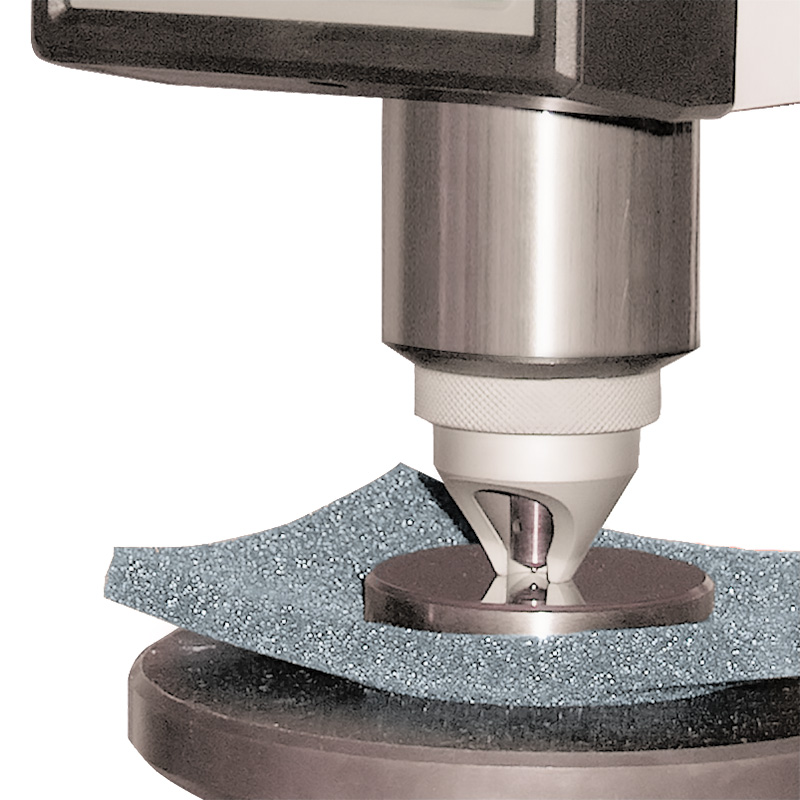

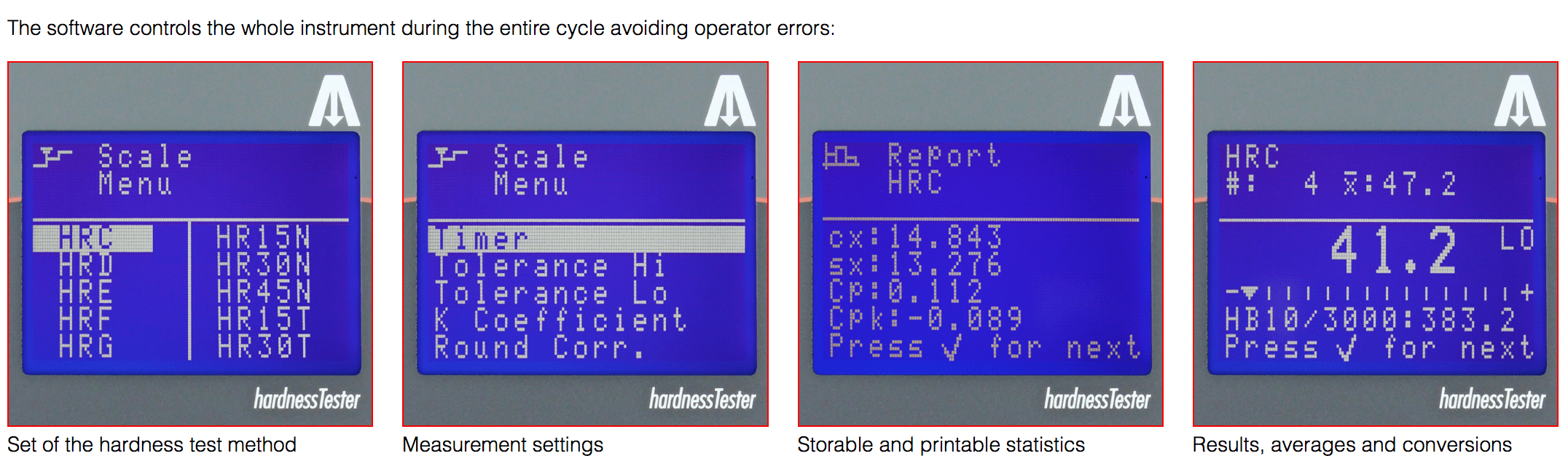

Portable hardness tester with magnetic base for Rockwell, Super-Rockwell, Brinell and Vickers testing methods. The first portable hardness tester that meets the international hardness standards ASTM E-18, E-10, E384 and DIN EN ISO 6508, 6507, 6506. The RSD MAG is a digital portable hardness tester with manual drive and automatic test sequence. Thanks to the magnetic clamping base, even very bulky components can be carried out directly in the production hall. The test direction is secondary because the test load is applied via a dynamometric load cell. A secure fixation on almost any surface, from round to flat, with independent alignment of the indenter to the measuring axis. LCD screen, user-friendly interface, real-time statistics and large archive storage are also included in the device. This hardness tester guarantees the highest accuracy and repeatability in every measurement.

For almost all metals: iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys.