Special wishes?

Automatic hardness testers according to customer requirements, especially designed for special components- or assembly line testing. For Rockwell, Vickers, Brinell, and Jominy test procedures, for measuring hardness on camshafts, crankshafts, gas bottles or gas pipes, roller bearings, large parts and much more – we build your testing device.

MRS BOT

Automatic hardness tester for your production line, especially for gas bottles or pipes.

Rockwell, Super-Rockwell, Brinell, Vickers/test load of between 3-3000 kg (29.45 to 29421 N)

Automatic and motorised measuring head with vertical travel, automatic clamping, and programmable via PLC.

In compliance with ASTM E10 and DIN EN ISO 6506 standards.

The load is regulated via load cells in a “Closed Loop”.

It is possible to equip a surface cutter with a depth precision of 0.01 mm that is also controlled via PLC.

LCD-touch screen and large hard disk for saving data.

Remote control via the internet for maintenance, additional training for operators, fast diagnosis or software updates.

GAS BOTTLE

Automatic hardness tester for the production line.

Rockwell – Brinell/Test load of between 10-3000 kg (98.07 – 29421 N)

Complete hardness tester including surface treatment for conveyor belts with automatic test procedure.

Brinell indents are automatically focussed and measured up.

The testing device can be adapted regarding test room height, jib length and length according to your requirements.

It is controlled via an LCD-touch screen bracket with a large hard drive for saving measuring results and test schedules.

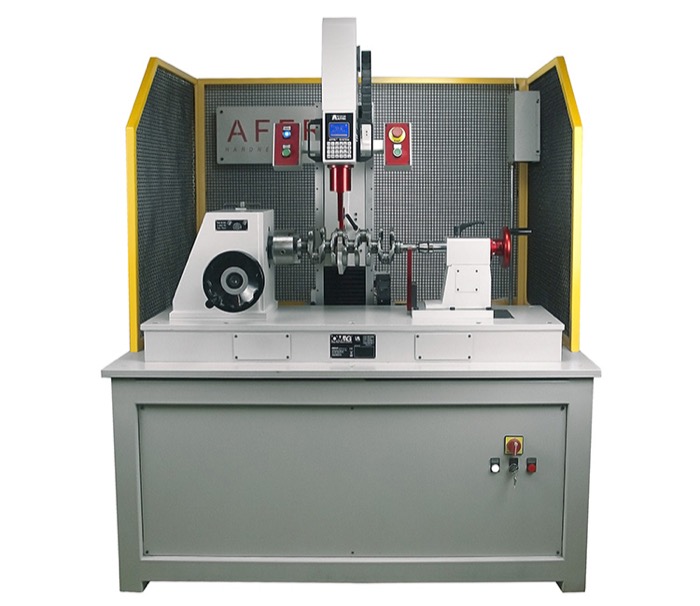

MATRIX

Automatic hardness tester for camshafts and crankshafts according to DIN EN ISO 6508, ASTM E18, E10 and E103

Automatic hardness tester for camshafts and crankshafts according to DIN EN ISO 6508, ASTM E18, E10 and E103

Rockwell – Super-Rockwell – Brinell/Test load of between 1-250 kg (9.807 – 2452 N)

The testing device is designed in a modular way such that it can receive objects to be tested of varying sizes without any problems.

Equipped with movements on 3 independent axles and a component rotation of 360 ° to enable testing points to be easily localised.

Precise and effective measuring already during the initial test.

The indenter is thin and long to be able to also carry out tests in between cams. An elongated shape and robust guide protect the indenter from impacts and enables tests to be carried out in immediate vicinity of connections.

These hardness testers can be used for measuring procedures directly during the ongoing manufacturing process such that personnel at the annealing furnace can be informed about the test results in real time.

JOMINY

Automatic Jominy hardness tester in compliance with DIN EN ISO 6508 and ASTM E18

Automatic Jominy hardness tester in compliance with DIN EN ISO 6508 and ASTM E18

Jominy – Rockwell – Super-Rockwell – Brinell/Test load of between 3-187.5 kg (29.45 to 1839 N)

Developed for testing several samples and extremely large surfaces. Individual samples or even several samples can be tested in compliance with ASTM E-18 and DIN EN ISO 6508 specifications. The sample can optically be shown with a fivefold lens magnification to clearly define the “Starting Point”. Automatic self-calibration in compliance with ASTM E-18, DIN EN ISO 6508 for three test blocks (hard, medium and soft). Standardised test samples are saved in the On-Board-Database, in order to simplify operation of the device. It is possible at any time to set up a customer-specific test cycle.

INTEGRAL SPRINGS

For testing springs according to DIN EN ISO 6506 and ASTM E10

Brinell measurements on spring coils with a built-in milling machine!