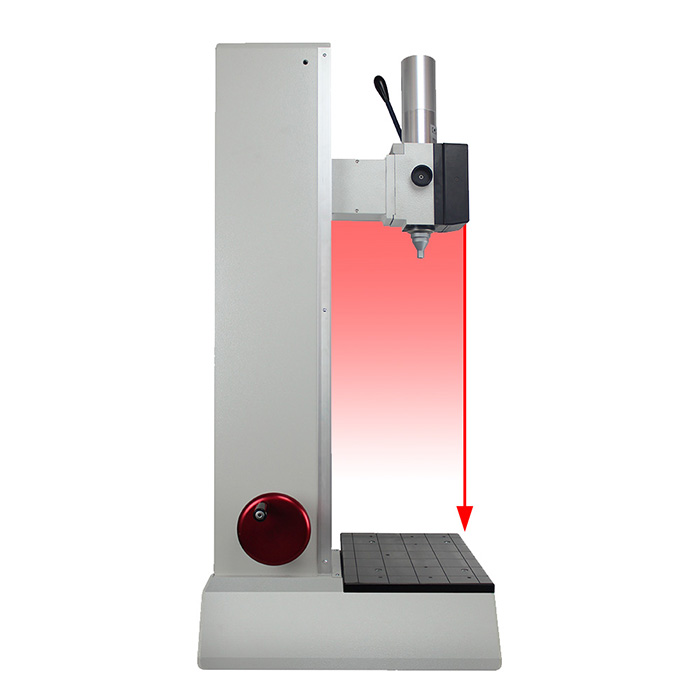

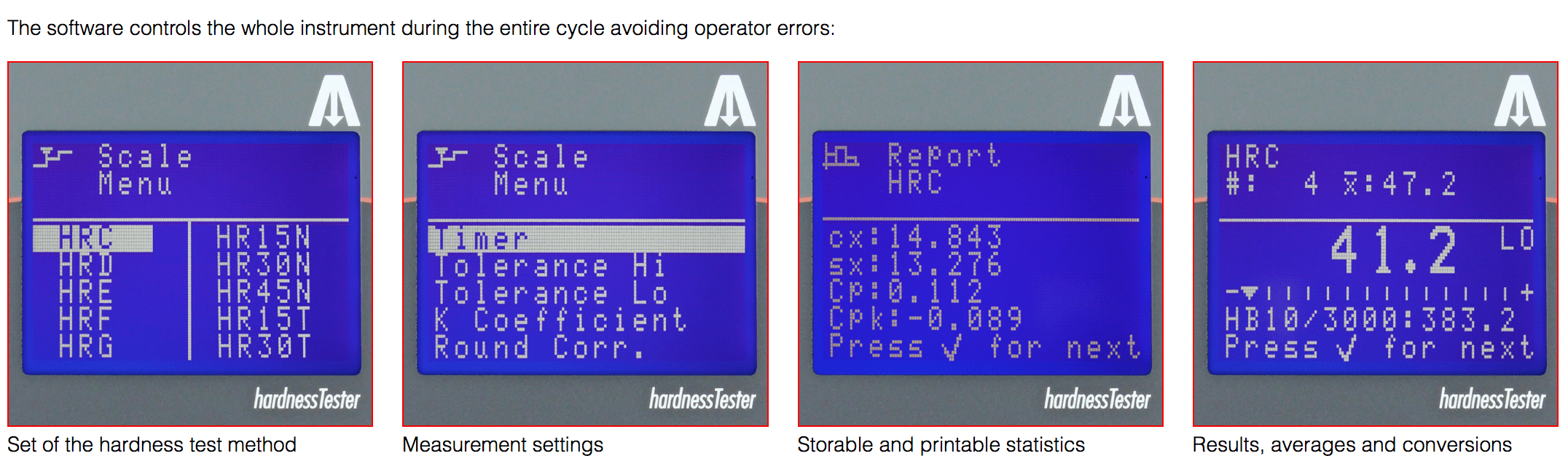

RSD SERIES

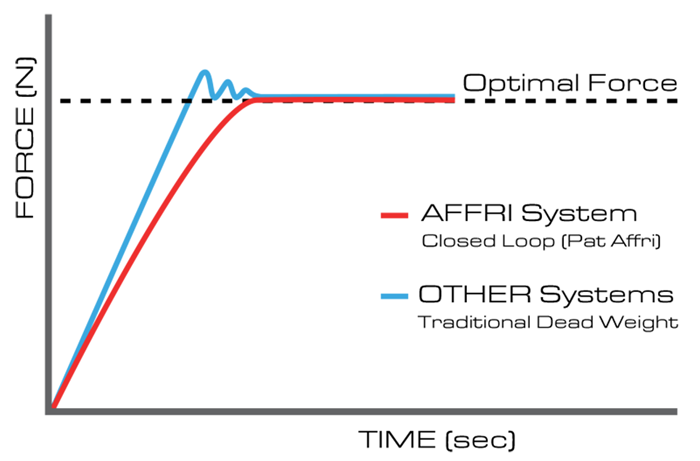

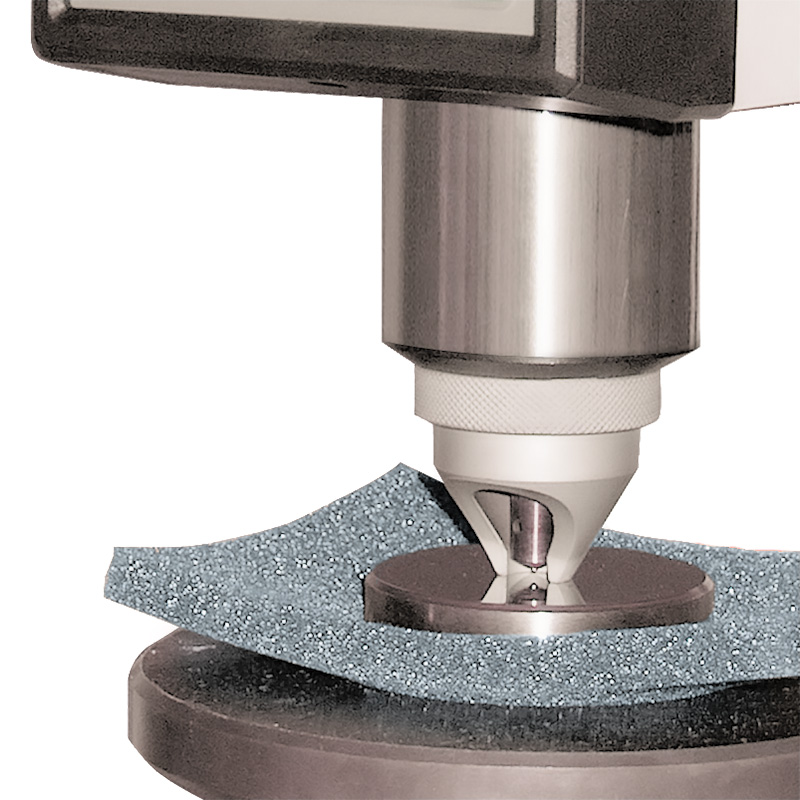

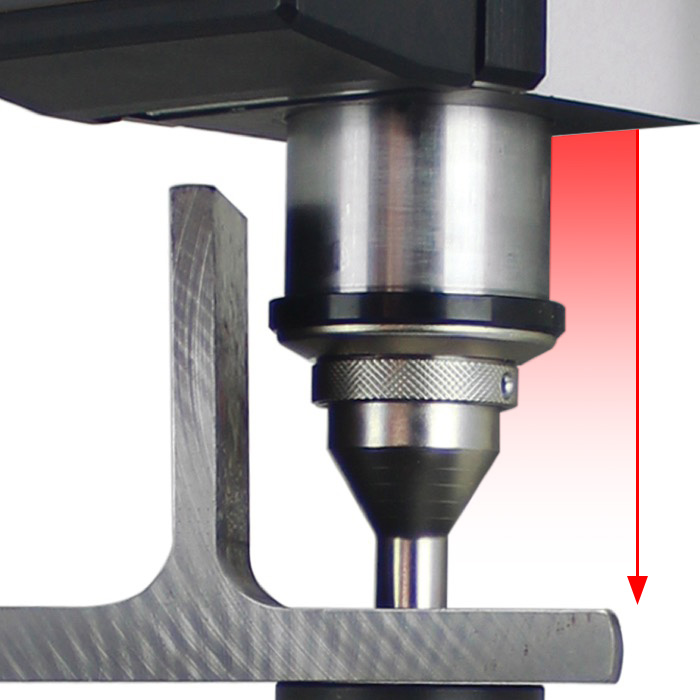

Semi-automatic hardness testers for Rockwell, Superficial Rockwell, Brinell and Vickers hardness test methods in compliance with ASTM and ISO standards. RSD Series are bench hardness testers for tough or lab applications. Rockwell and Brinell HBTW hardness values with absolute accuracy (better than 0.5 %) in every condition, accurate measurements even on the first test will eliminate the need for repeated tests. Load forces are applied through a dynamometric load cell which eliminates problems associated with dead weight systems on traditional testers. Digital durometers with LCD screen, user friendly interface, real time statistics, graphs and large archive storage. Hardness testing on all metals: iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys. Heat treatment, hardening, nitriding, cementation and hardfacing.